Standard Lifters was born in 2003 with the idea that high-quality, standardized die components would allow for superior production performance and savings for tooling stampers and tooling suppliers.Every day since, we’ve worked toward this goal.

We pride ourselves on innovation. It’s what drives us, every day, to continuously improve products to help progressive die tooling and die stamping operations. Twenty years later, we’re still working with the same goal in mind. Here’s a look back at the innovation that has led us to today.

2003: Rail Lifters Bring Standardization to the Die Component Market

At the start, Standard Lifters began with an idea. We saw a gap in the tooling market. How could we improve the process? Could we produce higher-quality, robust die parts that would last longer and reduce maintenance and downtime? Our answer was yes. Our original product line (and namesake), Rail Lifters, delivered a robust bolt on a ready-stock rail system that continues to be used today.

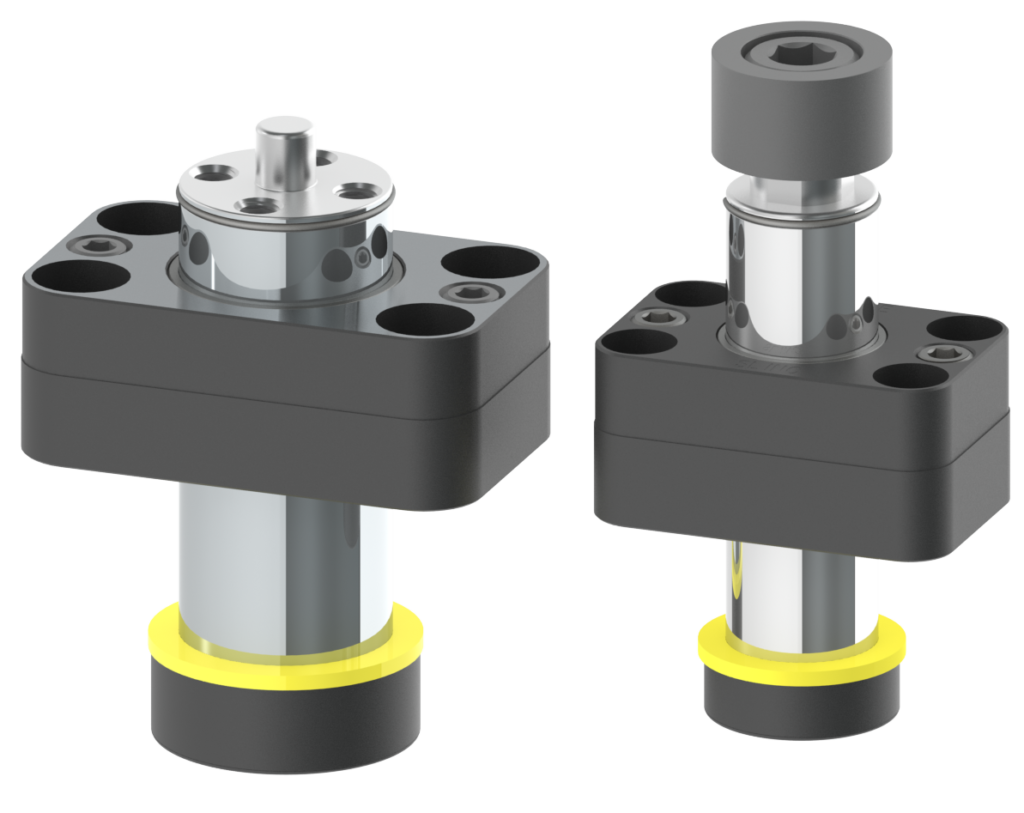

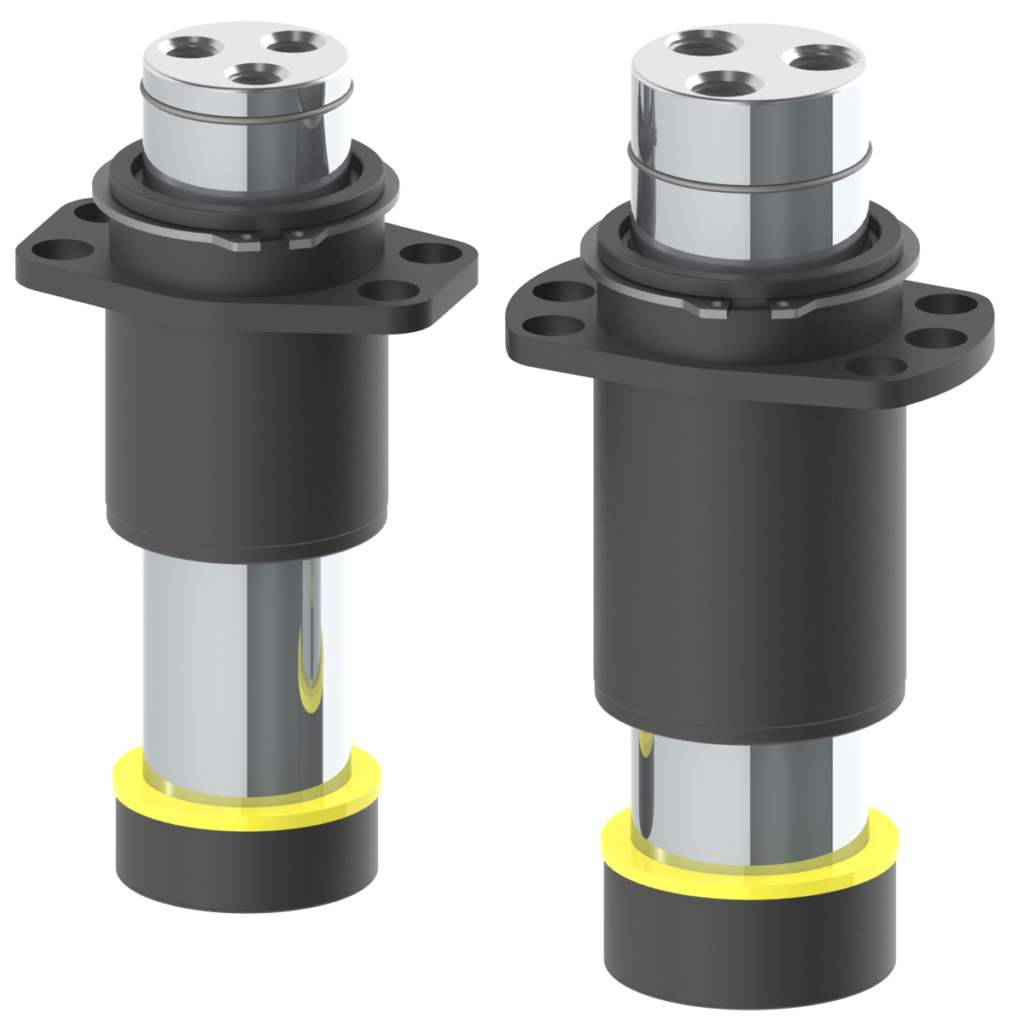

2005: Worldwide Industry-First Guided Keeper Launches

Before 2005, progressive die operations used the same conventional pins, bushings, and spools or keeper blocks as separate die components. Then we introduced the world’s first all-in-one guidance and retention assembly: the Guided Keeper. Replacing conventional pins, bushings, and spools/keeper blocks, our Gen 1 Guided Keepers delivered savings in design and build and longer-life production from a standardized component. We were the first, original, and patented design for the Guided Keeper.

2008: Gen 2 Guided Keeper Offers New Base Styles and Robust Pins

One of the best parts (no pun intended) about our jobs is that we get to interact with our customers daily. We truly desire honest feedback about how we can improve. And who better to tell us than those using them every day? Our Gen 2 Guided Keeper design introduced longer and more cost-effective bore-located bushing styles. We also delivered new pin connection styles to increase robustness for high-demand applications.

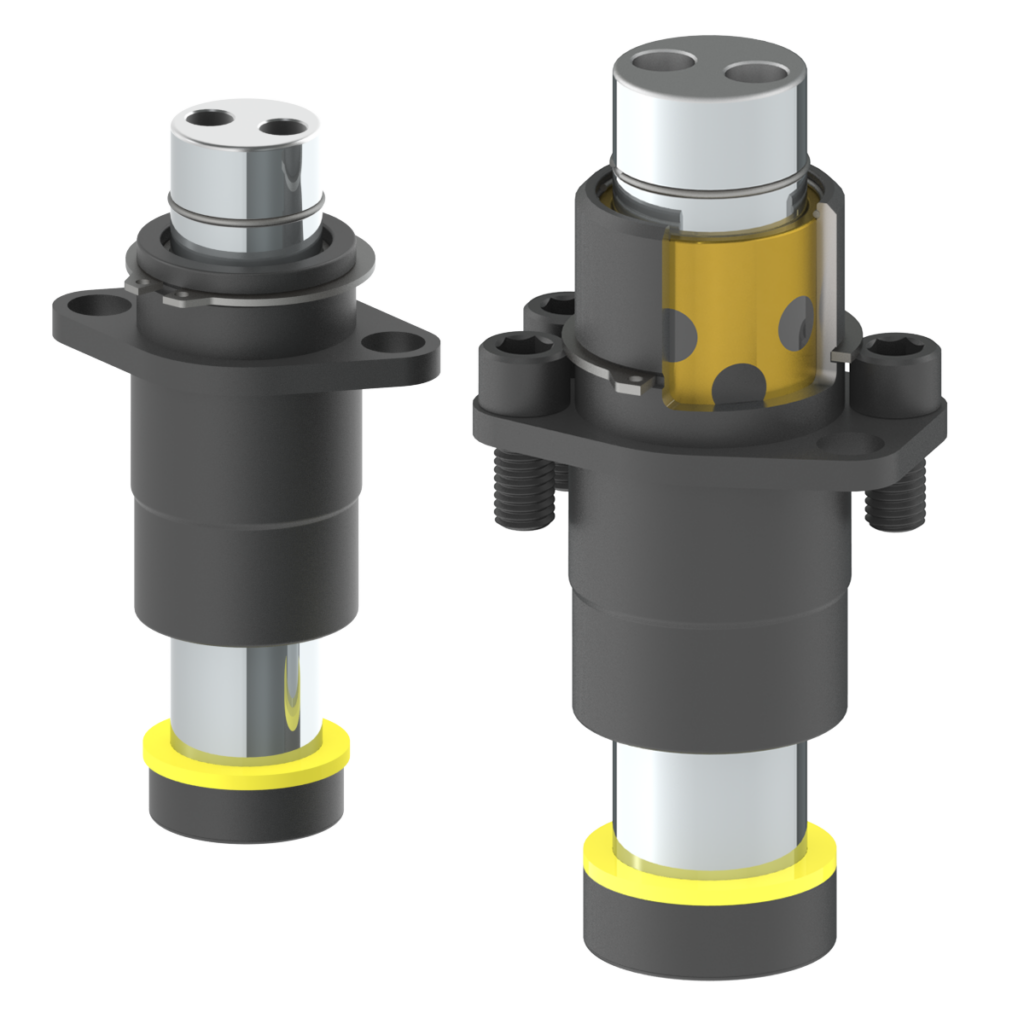

2010: Universal Gas Spring Clamps Provides Innovative Design

In 2010, we introduced our line of simple and effective Gas Spring Clamps. The innovative and economical design can be mounted with single-tap machining and utilized with any brand of nitrogen cylinder.

2012: World’s First All-in-One Pilot Assembly is the New Standard

We released a new industry standard for piloting: our all-in-one Pilot Assembly. It offers location and ejection in one unit, driven by a robust, long-life spring. Our Ejector Pin style Pilots are ideal for heavy-duty material, while our Round Stripper Pilots are suited for thin/soft stock with less spring pressure and more contact surface area.

2014: Long-Lasting Ejector Design Improves Performance

Seeing an opportunity to design a simple and all-in-one ejection product that lasts for the life of the tool, we engineered and introduced our Ejector product line.

2019: Ejector Upgrades and Tapered Pilots Advances Industry

To answer customer demand, we introduced a longer travel Ejector suited for part ejection and a line of off-the-shelf Tapered Pilots ideal for transfer tooling.

2020: Gen 3 Guided Keeper Expands for High-Demand Applications

We continued to gain valuable insights from our global customer base and introduced our newest generation of Guided Keepers. Continued innovation includes a new bushing option (bronze plugged) for high-demand applications, a new guide pin series for greater robustness, and our new “N” style, which allows for increased bushing configurations to maximize bushing length in your application.

2023: Celebrating 20 Years of Die Component Innovation

We started with the idea that high-quality, standardized die components would translate into superior production performance and savings for tooling suppliers. After 20 years, with six innovative product lines (and counting!), we continue to deliver on our promise: Making innovation the standard.

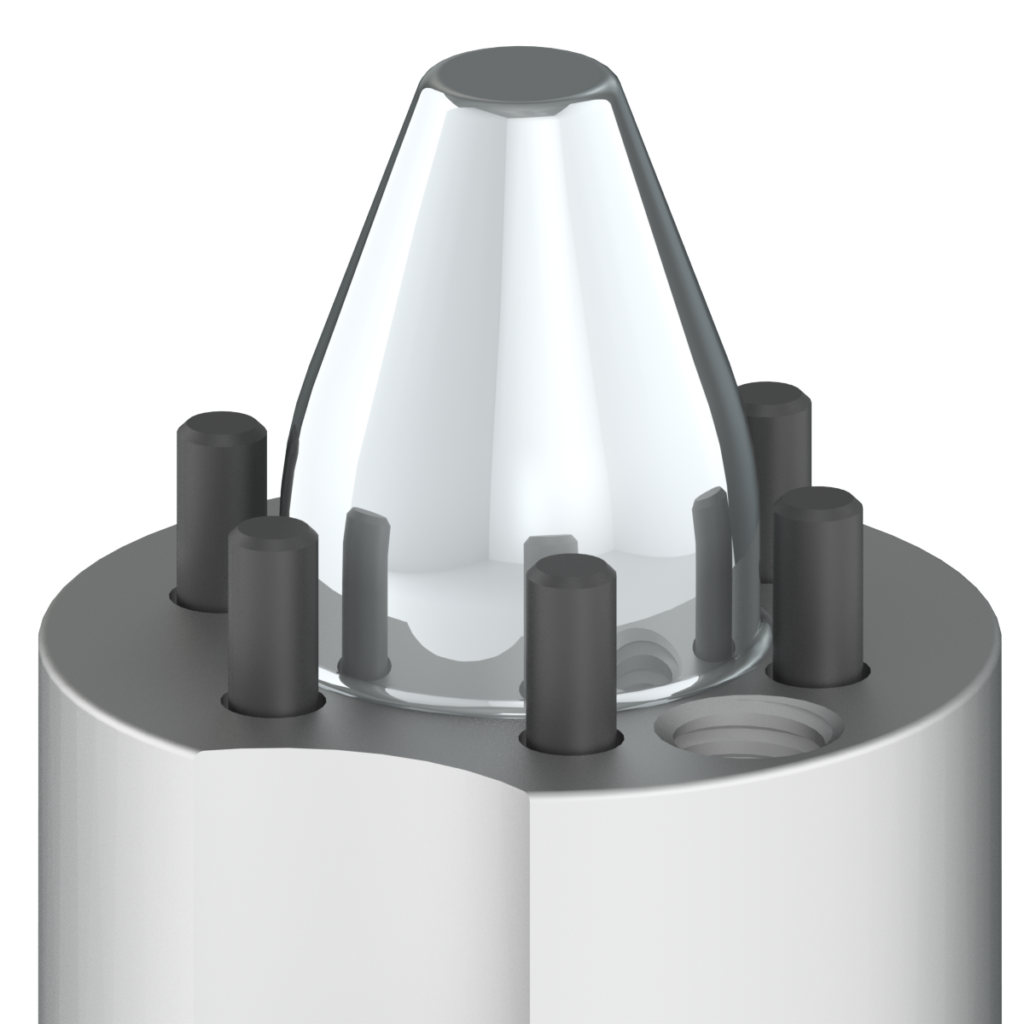

2024: Expanding with Four Tight Space Pilot Options

To answer continued customer demand, we introduced four new Pilot styles with a focus on tight space. Expanding on the success of our Pilot Assemblies, we now have an off-the-shelf and high-quality Pilot product option for all design applications.

A huge thank you to all of our customers who continue to work closely with us to improve their operations. We have a unique place in the industry that allows us to make a difference, and we are grateful.

If you have any feedback that you think could improve a product (or one we haven’t tried yet), reach out to get in touch with our team. Our customer service team is located in the USA and is always available for you.